Time: 2023-09-13 Source: Registered Fire Protection Engineer Author: Click: 1206 times

1. System partition

(3) Closed stairwells should adopt a natural ventilation system. Closed stairwells that cannot meet natural ventilation conditions should be equipped with a mechanical pressurized air supply system. When the closed stairwells of underground or semi-underground buildings (rooms) are not shared with above-ground stairwells and there is only one underground floor, a mechanical pressurized air supply system does not need to be installed, but an openable air vent with an effective area of not less than 1.2㎡ should be installed on the first floor. Exterior windows or evacuation doors that lead directly to the outdoors.

(4) Public buildings, industrial buildings with h≤50m and residential buildings with h≤100m

D. When the smoke-proof stairwell adopts natural ventilation in the part above the height of the podium, the independent front room, shared front room and shared front room of the podium without natural ventilation conditions should adopt a mechanical pressurized air supply system, and the independent front room The arrangement of the air supply vents in the room, shared front room and shared front room shall comply with the provisions of the preceding paragraph.

3) When scissor stairs are used, the mechanical pressurized air supply systems of the two stairwells and the front room should be set up independently.

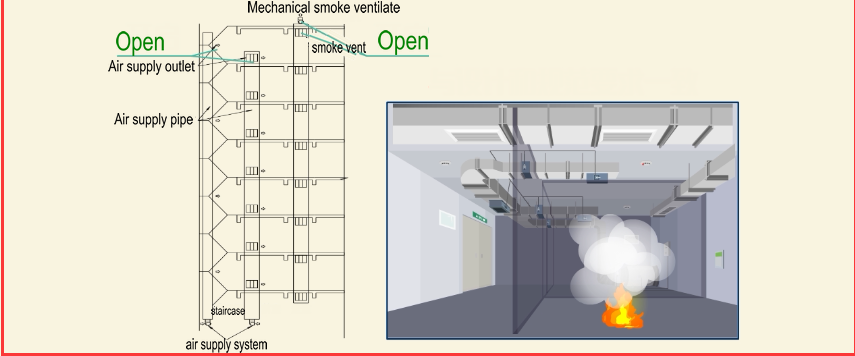

H. When a one-way air valve or electric air valve is installed on the air outlet duct or air inlet duct of the air blower, measures should be taken to automatically open the valve in case of fire.

C. The duct well of the mechanical pressurized air supply system should be separated from adjacent parts by a partition wall with a fire resistance rating of not less than 1.00h. When an access door must be installed on the wall, a Class B fire door should be used.

8. Natural ventilation and natural smoke exhaust requirements